Understanding the Core of Modern Machinery

In the intricate world of industrial machinery, the Diaphragm Coupling stands out as a critical component, engineered for precision, durability, and high performance. It belongs to a sophisticated family of Flexible Couplings, designed specifically to connect two shafts end-to-end and transmit power seamlessly. Unlike rigid couplings, its primary advantage lies in its ability to accommodate various types of misalignment—be it angular, axial, or parallel—between the connected shafts. This flexibility is essential in dynamic operational environments where perfect alignment is nearly impossible to maintain over time. By absorbing vibrations and compensating for these slight imperfections, this coupling protects delicate machinery from damaging stresses, ensuring smoother operation and extending the lifespan of the entire system.

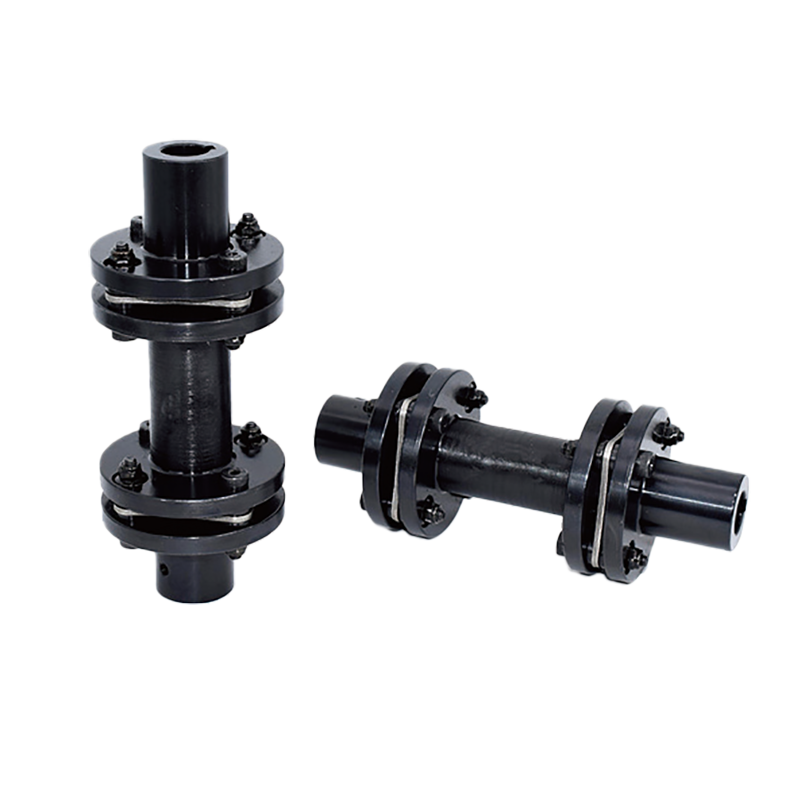

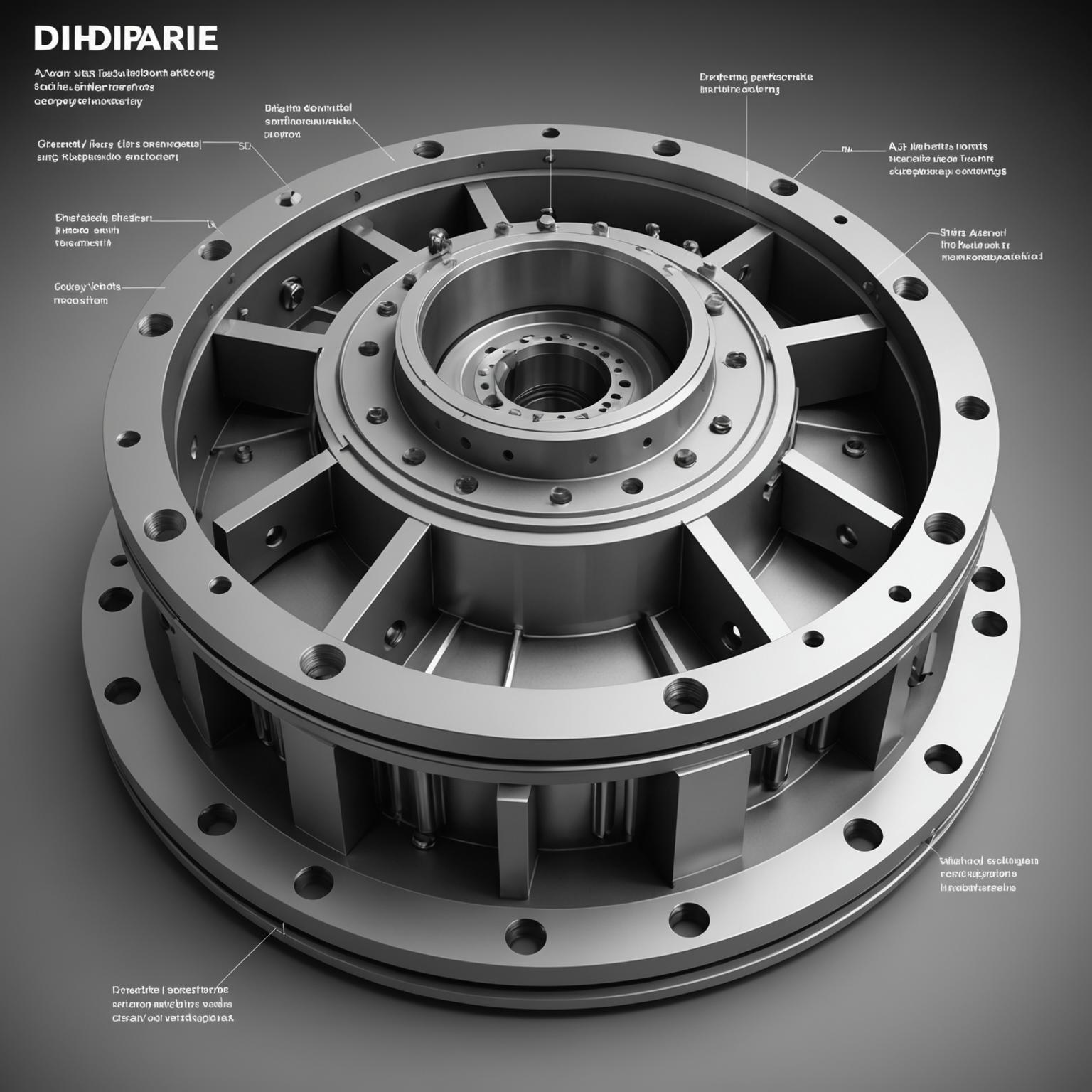

A Closer Look at Diaphragm Coupling Design

The effectiveness of this connection hinges on its sophisticated Diaphragm Coupling Design. At its heart are one or more flexible metal diaphragms, typically crafted from high-grade stainless steel. These thin, meticulously engineered plates are bolted together, forming a pack that connects the driving and driven hubs. The magic happens as these diaphragms flex to handle shaft misalignments. The surrounding Coupling Components, such as the hubs, spacers, and high-tensile bolts, are equally vital. For instance, innovative designs often feature a cone sleeve, which provides a reliable grip and simplifies the mounting process, ensuring a secure and balanced connection. Every element is carefully selected and manufactured to resist corrosion and wear, reflecting a commitment to quality that translates into long-term performance and reliability.

Ensuring Flawless Torque Transmission

The fundamental purpose of any coupling is Torque Transmission, and the diaphragm style excels in this regard, especially in applications that demand precision. It is known as a torsionally rigid coupling, meaning it does not have the 'wind-up' or backlash common in other types of Mechanical Couplings. This zero-backlash characteristic is crucial for applications in automation, robotics, and high-speed machinery where exact positioning and motion control are paramount. The power from one shaft is transferred to the other with exceptional fidelity. This efficient Torque Transmission ensures that there is no loss of motion or energy, allowing the system to operate at peak efficiency. This capability makes the Diaphragm Coupling a superior choice for high-performance systems where accuracy cannot be compromised.

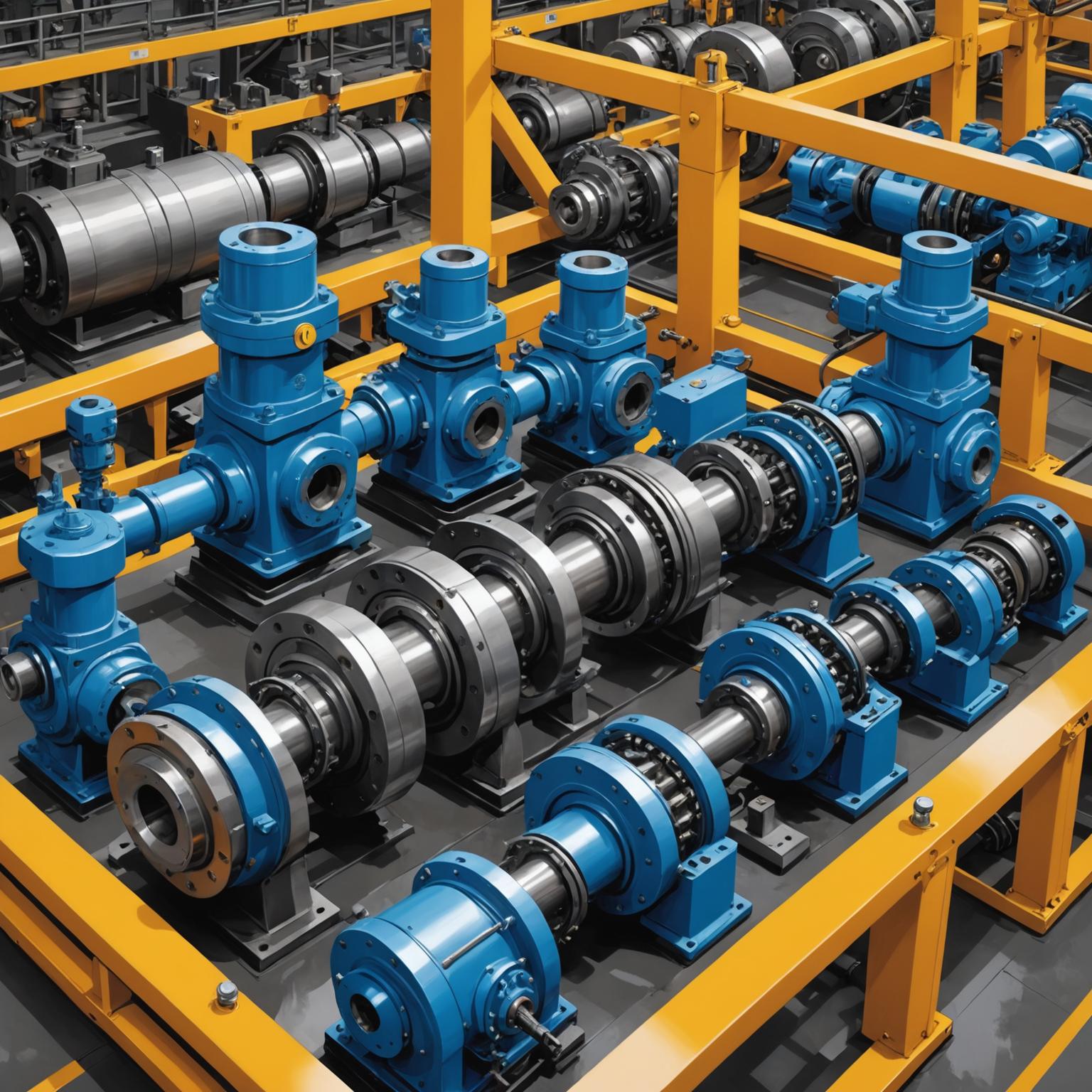

Versatility in Action: Key Coupling Applications

The unique combination of flexibility and torsional rigidity opens up a vast range of Coupling Applications across numerous industries. In the energy sector, they are trusted to connect turbines to generators, where reliability is non-negotiable. In manufacturing and automation, they link servo motors to ball screws and other precision equipment, maintaining the accuracy required for complex tasks. You can also find them in pumping systems, fans, and compressors, where their low-maintenance, lubrication-free design is a significant advantage. The diverse Coupling Applications demonstrate the component's adaptability. Whether the environment demands high speed, high torque, or extreme precision, these robust Mechanical Couplings provide a dependable solution, making them a preferred choice for engineers designing for performance and longevity.

The Cornerstone of Modern Engineering

Ultimately, the Diaphragm Coupling is more than just a simple connector; it is a cornerstone of modern engineering solutions. Its elegant Diaphragm Coupling Design, which masterfully blends robust Coupling Components with flexible elements, provides a solution that is both strong and forgiving. It stands as a testament to how thoughtful engineering can solve complex mechanical challenges, delivering flawless Torque Transmission even under imperfect conditions. For any industry where precision, efficiency, and reliability are the pillars of success, this component is not just a part—it is an investment in operational excellence and mechanical integrity.