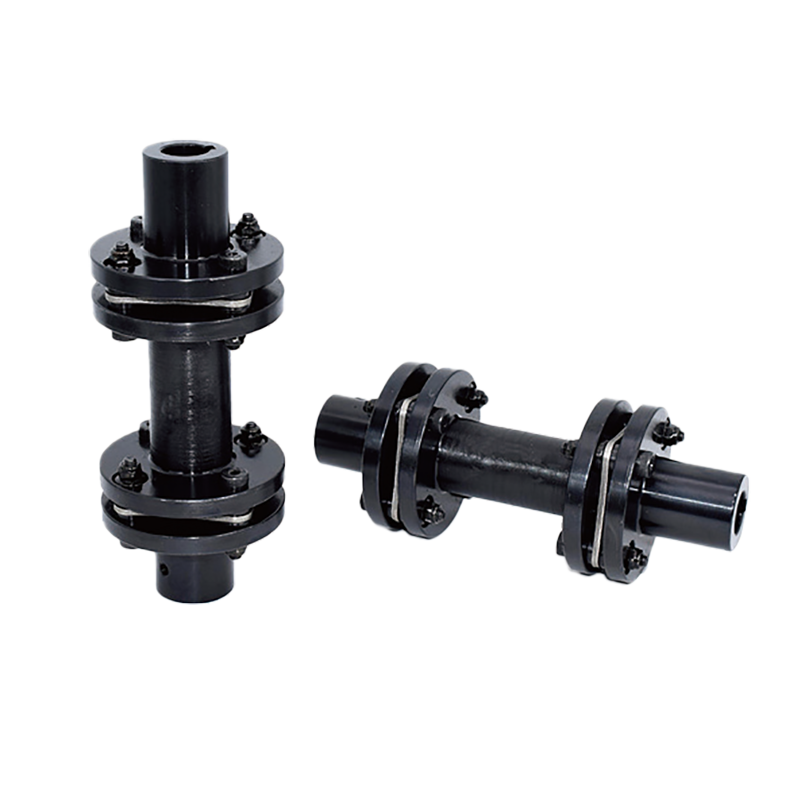

1. Enhanced Torque Transmission and Durability

One of the most significant advantages of this coupling is its ingenious architecture focused on superior Torque Transmission. It incorporates a unique tapered sleeve, a design feature that significantly improves how torque is transferred between shafts while simultaneously reducing stress concentration at critical points. This intelligent design not only ensures maximum operational efficiency but also extends the overall lifespan of the connected mechanical systems. By minimizing wear and tear, businesses can benefit from reduced maintenance costs and greater system reliability over time.

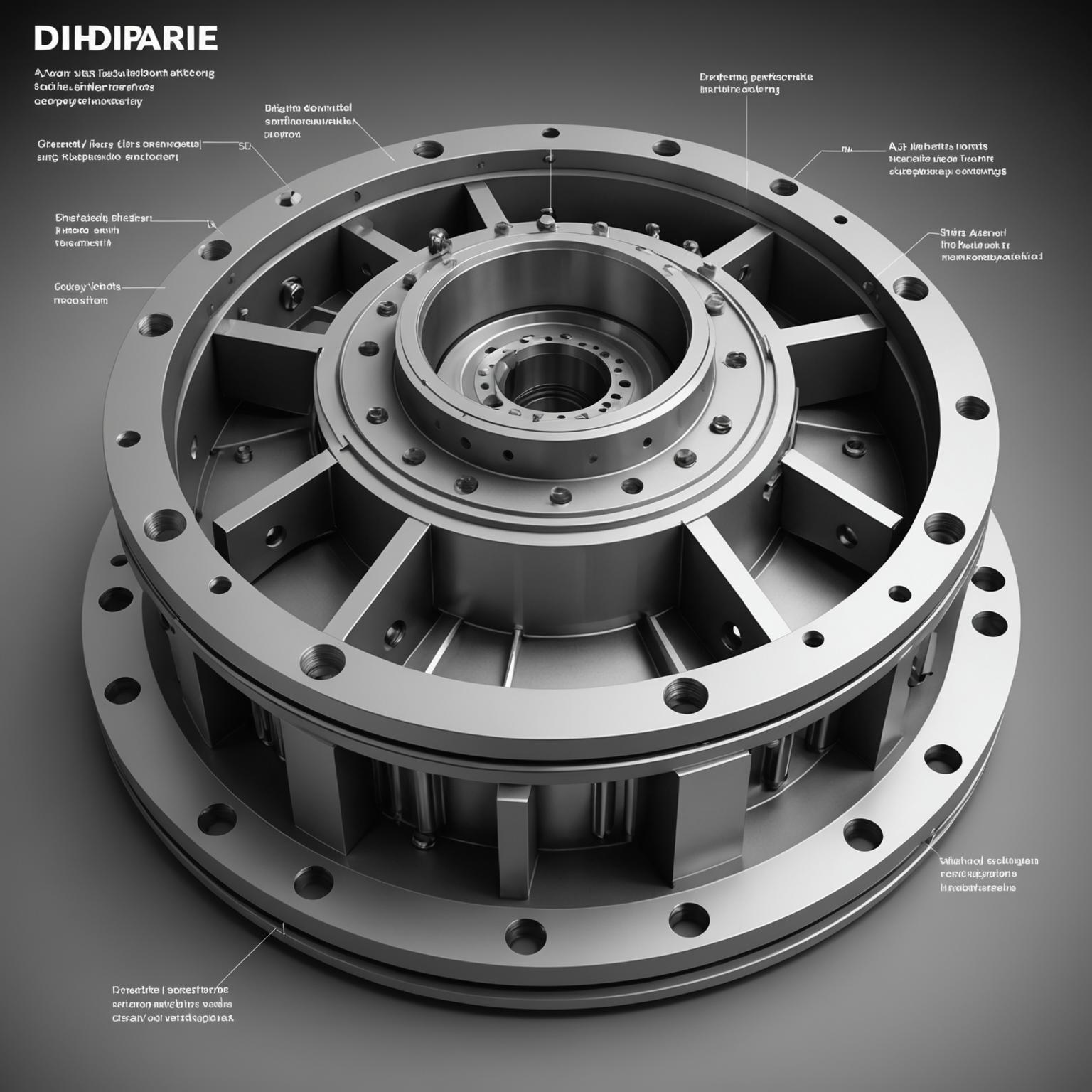

2. Innovative Diaphragm Coupling Design for Flexibility

The core of this coupling's performance lies in its advanced Diaphragm Coupling Design. It is engineered to function as one of the most effective Flexible Couplings on the market. Composed of multiple layers of meticulously engineered, high-grade stainless steel, the diaphragm itself is built to accommodate misalignment. This inherent flexibility allows the coupling to compensate for axial, angular, and parallel misalignments between shafts without sacrificing operational integrity. This capability is crucial in dynamic systems where perfect alignment is difficult to maintain, preventing premature wear on bearings and other components.

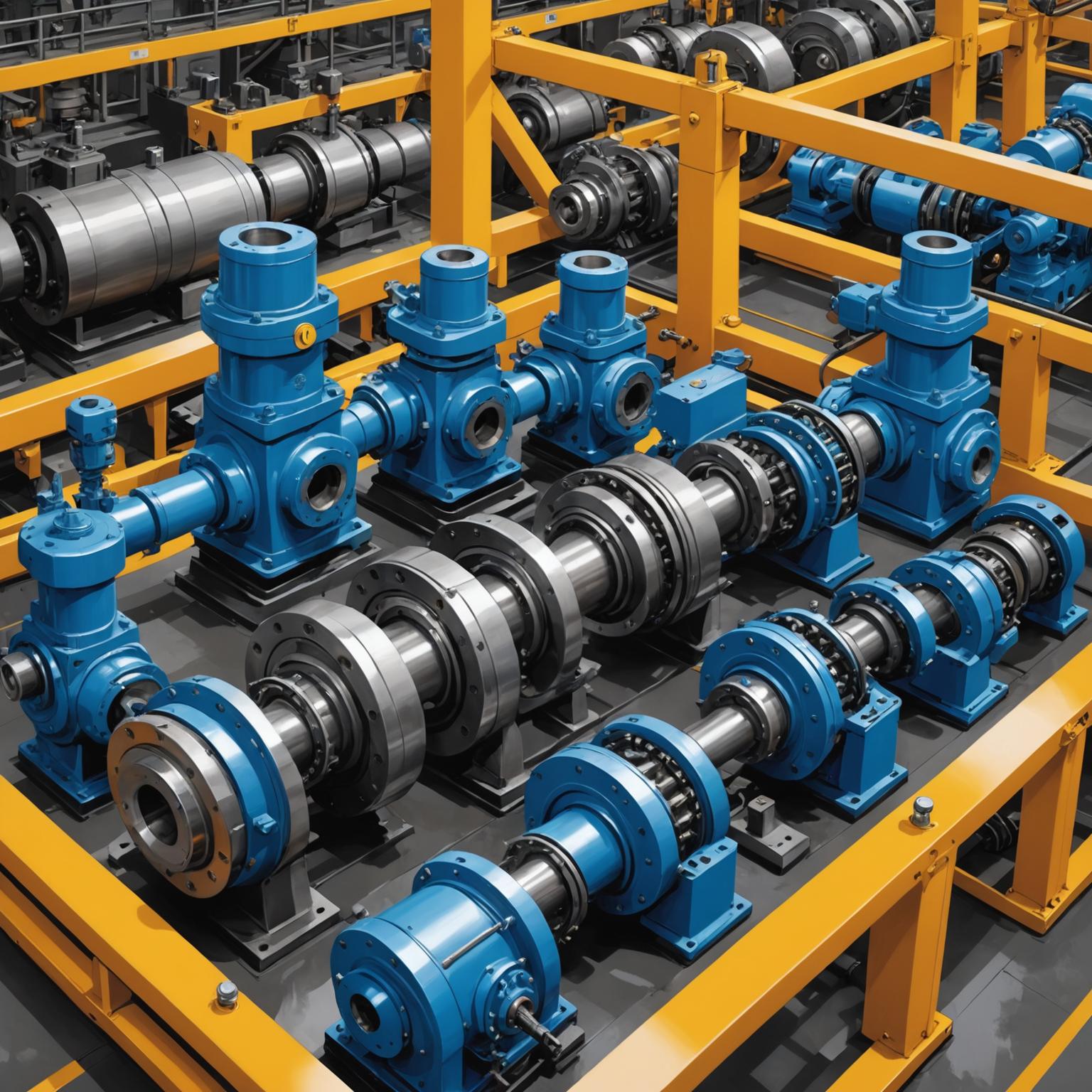

3. Versatility Across Diverse Coupling Applications

The compact and lightweight nature of the tapered sleeve diaphragm coupling makes it an incredibly versatile solution for a wide range of Coupling Applications. Its space-efficient design allows for seamless integration into complex machinery setups where space is at a premium. This versatility makes it an ideal choice for demanding industries, from automotive manufacturing to power generation. Furthermore, it provides superior vibrational damping and noise reduction, which enhances the overall performance, precision, and reliability of the equipment it serves, contributing to a safer and more efficient work environment.

4. Premium Coupling Components for Reliability

Reliability in harsh industrial environments is non-negotiable, and this coupling delivers through the use of premium Coupling Components. The entire assembly is crafted from high-grade materials, most notably corrosion-resistant stainless steel. This material choice ensures consistent performance and exceptional longevity, even when exposed to moisture, chemicals, or extreme temperatures. Every component, from the tapered sleeve to the diaphragm plates, is manufactured to the highest standards, guaranteeing that the coupling will not be a point of failure in your critical machinery.

5. Simplified Installation and Maintenance

Downtime is a significant cost in any industrial operation. This diaphragm coupling is engineered with a modular design that greatly simplifies installation and replacement. The components can be quickly assembled and disassembled, which minimizes the time your equipment is offline for maintenance or repairs. This user-friendly feature ensures that your systems can return to peak operational efficiency with minimal interruption, boosting productivity and reducing the labor costs associated with complex maintenance procedures.

In conclusion, the Tapered Sleeve Diaphragm Coupling represents a pinnacle of modern engineering, offering a robust solution that excels in Torque Transmission and operational flexibility. Its advanced design, premium components, and suitability for various applications make it a superior choice over many conventional Flexible Couplings. By investing in this technology, industries can enhance system reliability, reduce maintenance burdens, and ensure the precise, dependable performance of their most critical equipment for years to come.