The Core of Mechanical Couplings

At their heart, all Mechanical Couplings serve the fundamental purpose of joining rotating shafts to transmit power. However, where a diaphragm-style coupling truly excels is in its ability to perform this function under demanding conditions without introducing backlash. Unlike couplings that rely on lubricated, moving parts that can wear over time, a diaphragm coupling operates through the flexing of its metallic plates. This design ensures a robust and maintenance-free connection, providing a direct and unwavering link between the driving and driven components, which is crucial for the longevity and performance of the entire mechanical system.

Mastering Efficient Torque Transmission

The primary objective of any coupling is effective Torque Transmission, and the diaphragm variant achieves this with remarkable proficiency. Its design ensures that rotational power is transferred smoothly and consistently, without the energy loss or operational lag associated with backlash. This torsional stiffness is a key advantage, especially in applications requiring precise positioning and synchronized movement. By creating a solid connection for torque, while remaining flexible for alignment, these couplings protect sensitive components like bearings and seals from the damaging forces that can arise from shaft misalignment, thus enhancing overall system durability.

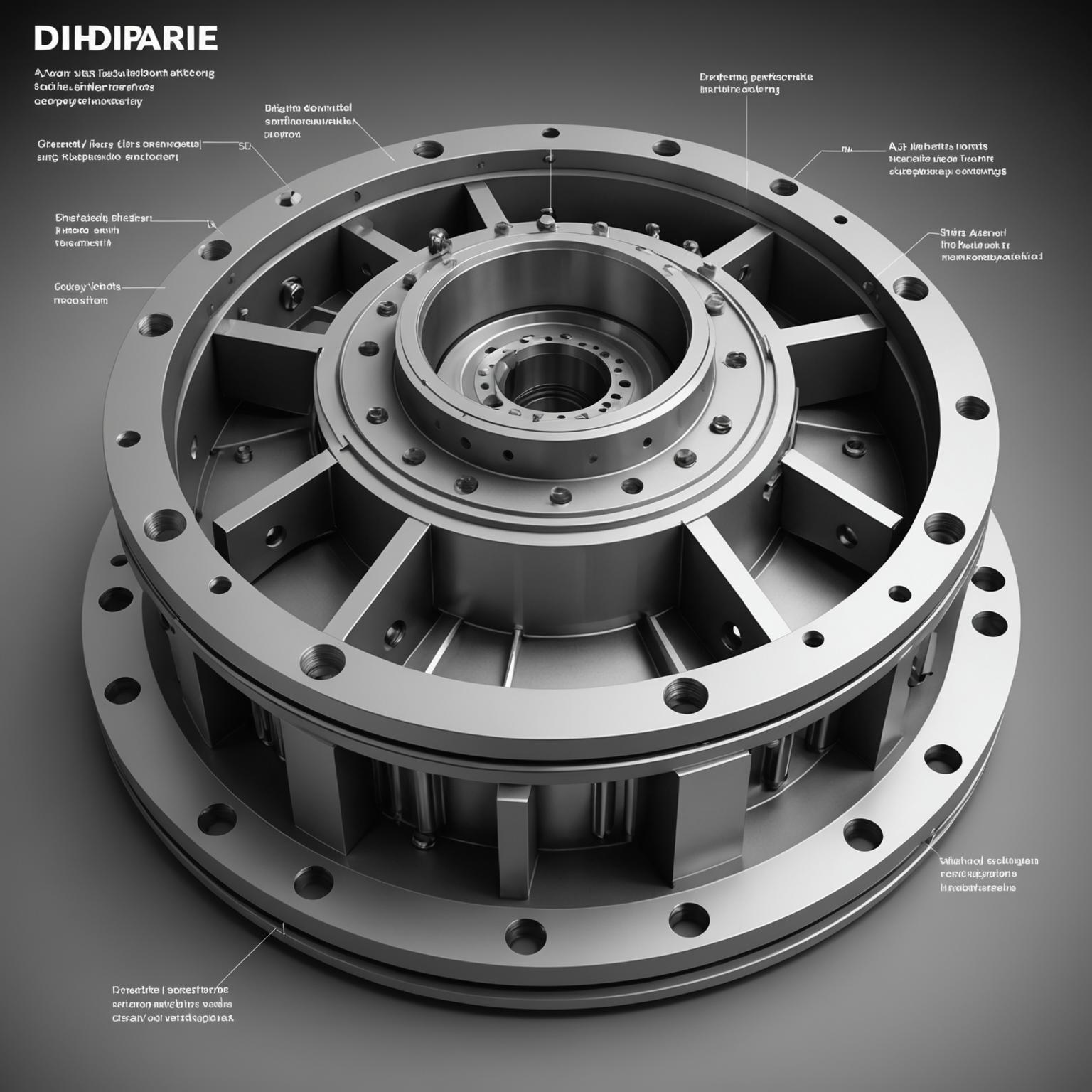

Anatomy of the Diaphragm Coupling Design

A closer look at the Diaphragm Coupling Design reveals its elegant simplicity and sophisticated function. The core Coupling Components consist of one or more flexible metal diaphragms, typically made of stainless steel, which are bolted to the input and output hubs. In a double-disc design, a central spacer connects two diaphragms, significantly increasing the coupling’s capacity to compensate for parallel, angular, and axial shaft misalignments. This arrangement allows the shafts to move relative to each other without imparting significant stress, all while the thin, profiled diaphragms flex to absorb these shifts. This clever engineering ensures that the connection remains strong and the power flow uninterrupted.

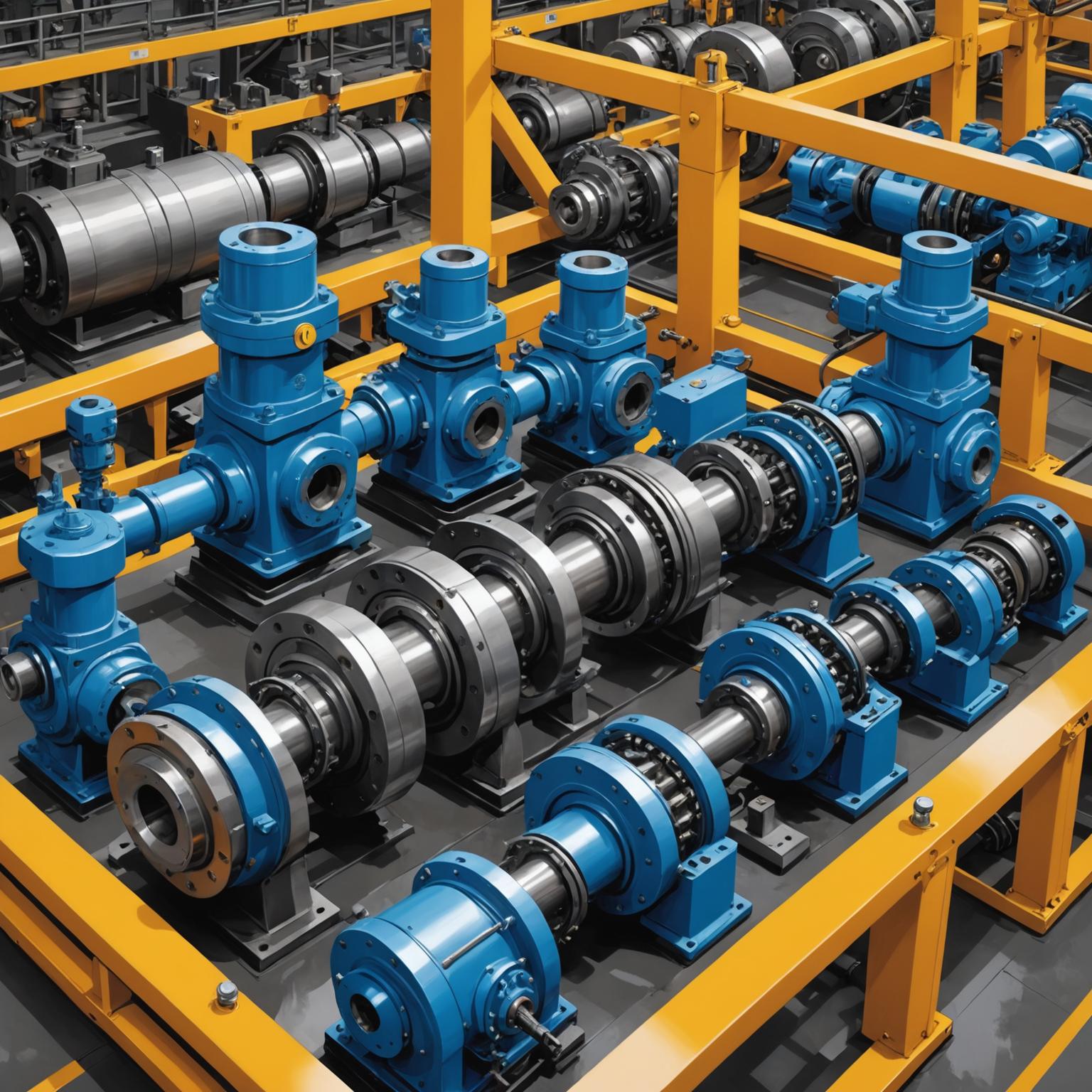

Versatile and Critical Coupling Applications

The unique combination of torsional rigidity and misalignment capability opens up a vast range of Coupling Applications for these advanced components. They are indispensable in high-performance industries where precision is non-negotiable. You will find them in gas turbines, high-speed compressors, industrial pumps, printing presses, and precision robotics. In each scenario, the demand for reliable, maintenance-free operation under continuous or high-speed conditions makes the diaphragm coupling the ideal choice, ensuring that equipment runs smoothly and efficiently for extended periods.

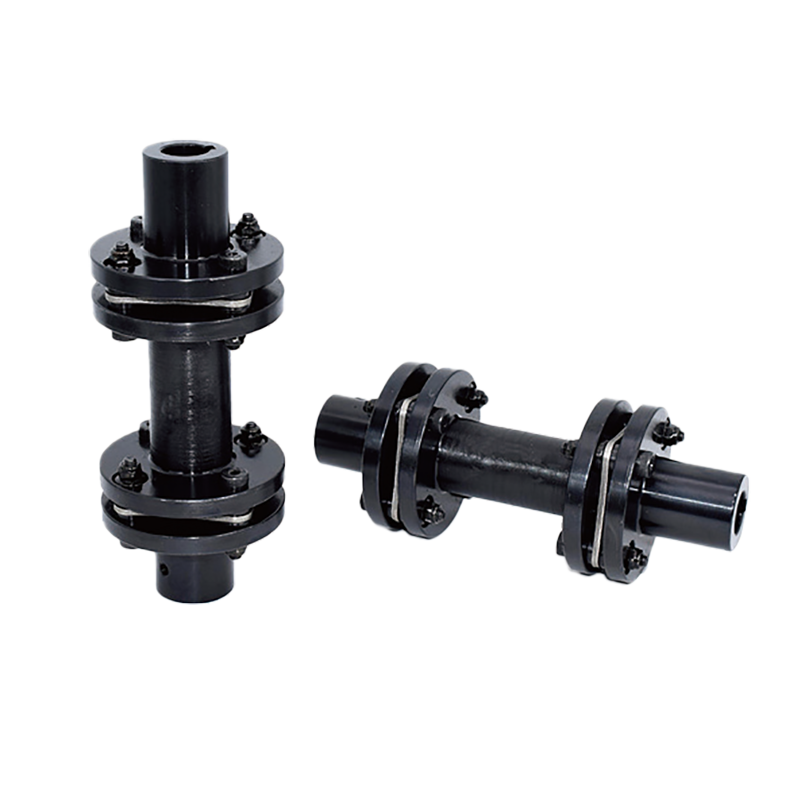

The Evolution of Flexible Couplings

Modern engineering continues to refine these essential devices, leading to innovations like the Cone Sleeve Double-Disc Flexible Diaphragm Coupling. This advanced iteration enhances the core benefits with user-focused features. The cone sleeve mechanism, for example, simplifies the installation process and provides a superior grip on the shaft, ensuring a secure fit that optimizes Torque Transmission. A sleek, protective finish not only adds aesthetic value but also provides resistance against environmental factors. Such advancements represent the ongoing evolution of mechanical components, where state-of-the-art technology and thoughtful design converge to meet the ever-increasing demands of modern industry, pushing the boundaries of performance and reliability.