Understanding Diaphragm Coupling Design and Components

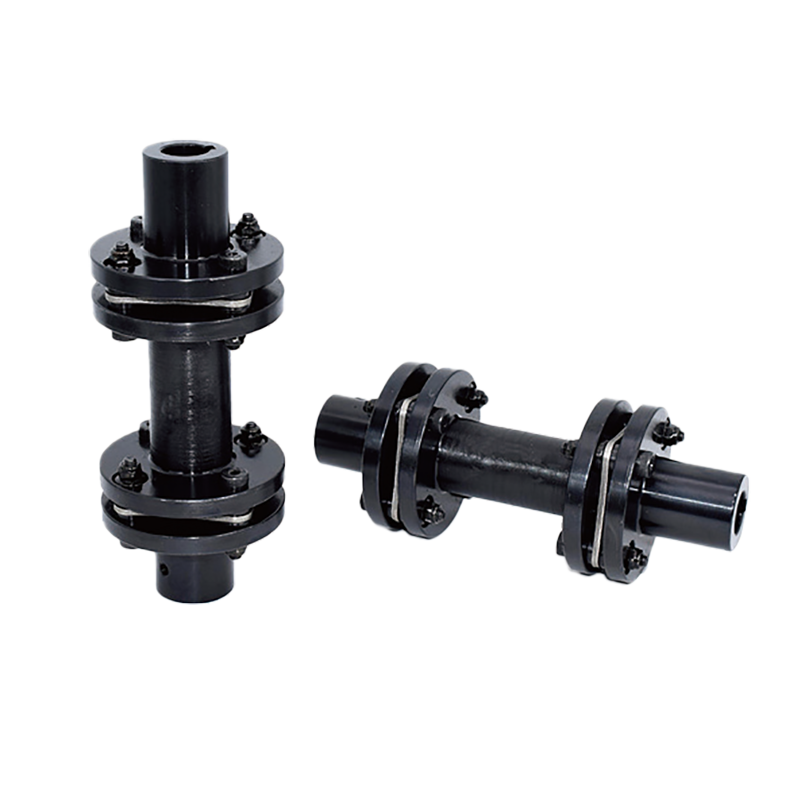

The effectiveness of this coupling lies in its innovative Diaphragm Coupling Design. Typically crafted from high-grade alloy steel, these couplings are built for strength and resilience. The core of the device consists of one or more flexible membranes or discs, which are bolted to the input and output hubs. These membranes are the key Coupling Components that allow the unit to flex and absorb parallel, angular, and axial misalignments between connected shafts. This prevents harmful stress from being transferred to sensitive equipment like bearings and seals, significantly extending the lifespan of the entire machinery setup. Advanced designs, such as the conical sleeve model, further enhance this flexibility without sacrificing structural integrity.

How Diaphragm Couplings Excel in Torque Transmission

When it comes to Torque Transmission, few solutions can match the precision of a diaphragm-style coupling. The solid-state construction, with its tightly bolted membranes, creates a connection with zero backlash. This is a crucial advantage over many other Mechanical Couplings that may have play or slop in their design, leading to inaccuracies in positioning and timing. The ability to transmit torque with high fidelity makes them ideal for applications requiring precise motion control, such as in servo systems, printing presses, and packaging machinery. The direct power transfer ensures that the machine operates exactly as intended, without the energy loss or wear associated with less rigid connectors.

Key Benefits and Common Coupling Applications

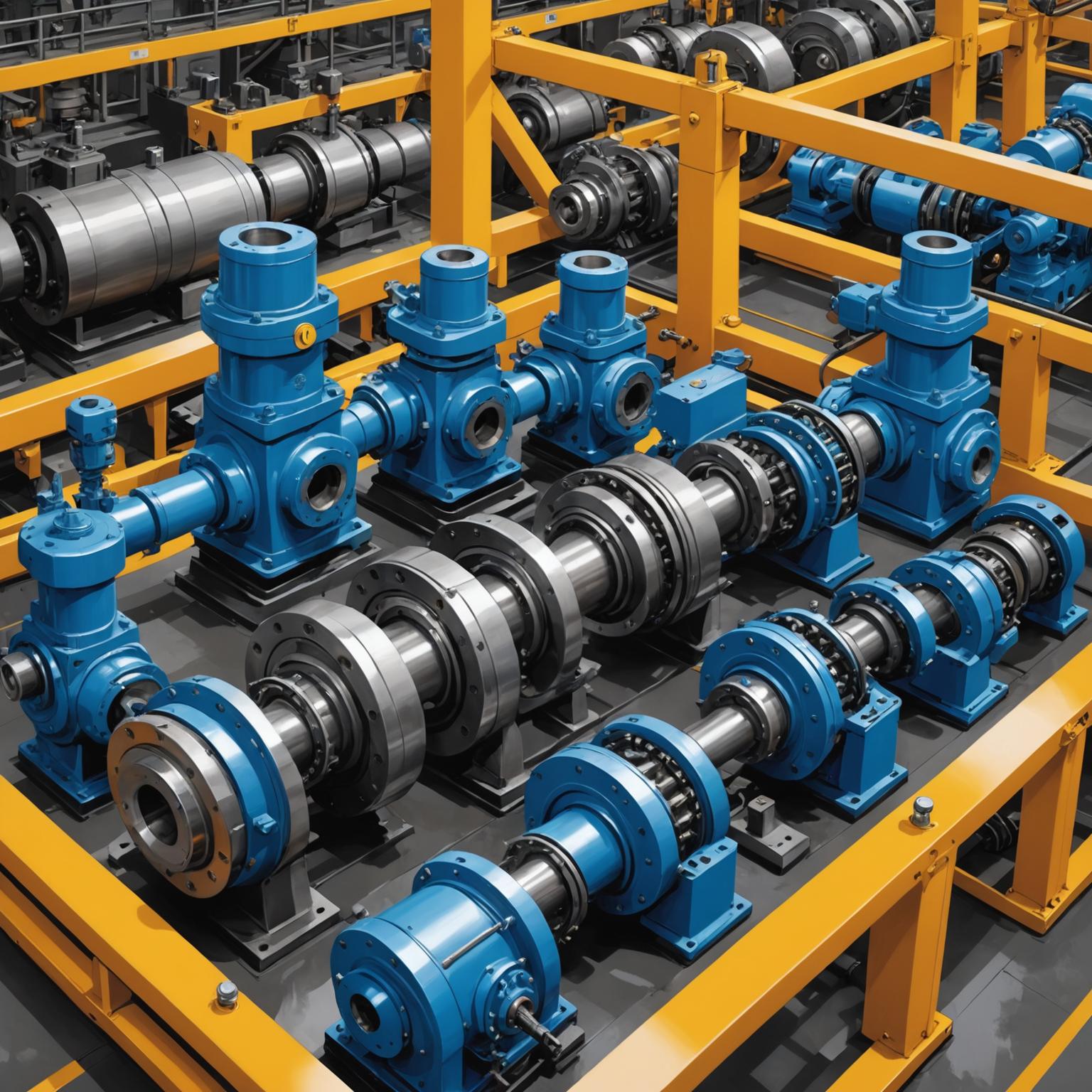

Beyond their primary functions, these couplings offer a host of operational benefits. One of the most significant advantages is their maintenance-free design. Because they have no moving parts that rub against each other, they do not require lubrication, which eliminates downtime for maintenance and reduces operational costs. Their compact, all-metal construction also makes them durable and resistant to harsh environmental conditions. These features make them perfect for a wide range of Coupling Applications, including pumps, compressors, fans, and industrial production machinery. Essentially, any system that demands high reliability, precision, and minimal maintenance can benefit from this advanced technology.

Choosing and Installing Your Diaphragm Coupling

Selecting the right coupling for your needs involves considering factors like torque requirements, the amount of expected misalignment, and rotational speed. It is essential to choose a model rated for your specific operational demands to ensure safety and performance. Fortunately, modern Diaphragm Coupling models are designed for straightforward installation. Many incorporate user-friendly features like self-centering capabilities, which simplify the setup process and ensure perfect alignment with minimal effort. This easy assembly reduces installation time, allowing you to get your machinery up and running more quickly and efficiently, solidifying its status as a superior choice for demanding industrial connectivity.