Understanding the Role of Mechanical Couplings in Modern Machinery

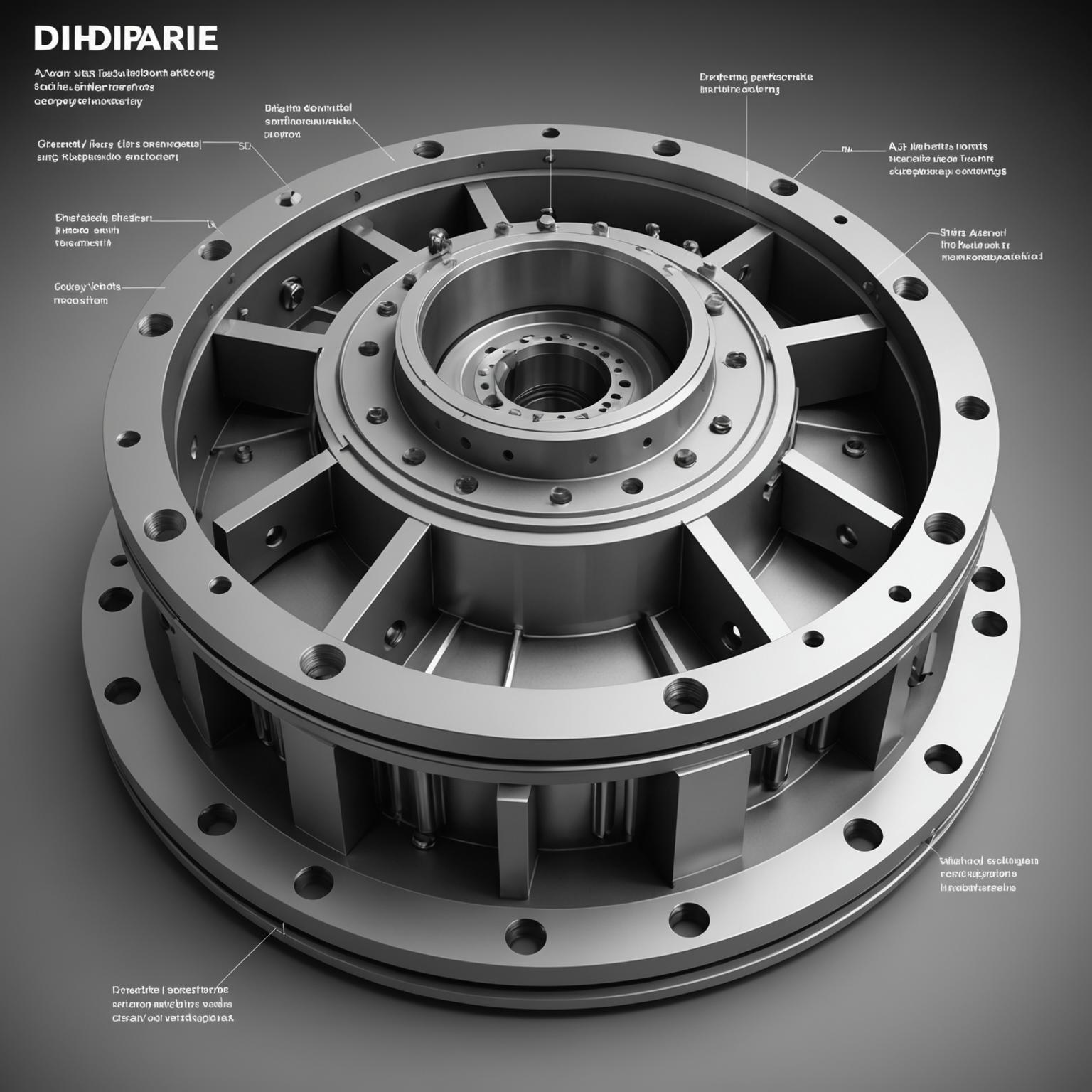

In the intricate world of mechanical engineering, the seamless transfer of power from one shaft to another is fundamental. This critical function is performed by a variety of mechanical couplings, each designed for specific operational demands. Among the many options, Flexible Couplings stand out for their ability to accommodate misalignment between shafts, a common occurrence in real-world systems. While many types exist, the Diaphragm Coupling represents a pinnacle of engineering for applications that demand high precision and reliability, setting it apart from other common solutions in terms of performance and design.

Diaphragm Couplings vs. Elastomeric Couplings: A Clash of Materials and Performance

When selecting a coupling, the first major comparison is often based on material and construction. The Diaphragm Coupling Design is characterized by its metallic, all-metal construction, typically featuring a series of thin, layered metal discs. These discs flex to accommodate angular, parallel, and axial misalignment. This all-metal build results in high torsional rigidity and zero backlash, meaning there is no play or slop during the transfer of power. This is crucial for systems requiring precise positioning and motion control. In contrast, elastomeric couplings (like jaw or tire types) utilize a flexible polymer or rubber element between hubs. While these elements are excellent at damping vibration and shock loads, they inherently possess more 'wind-up' or torsional flexibility, which is unsuitable for applications needing exact rotational accuracy. Furthermore, the performance of elastomeric couplings can degrade in extreme temperatures or when exposed to certain chemicals, a limitation not shared by their robust metallic counterparts.

Maintenance and Precision: Diaphragm Couplings vs. Gear Couplings

Another common high-torque solution is the gear coupling. While effective in transmitting high levels of power, its operational principle introduces different considerations. Gear couplings function through the meshing of geared hubs and sleeves, requiring regular lubrication to prevent wear and failure. This need for grease or oil creates a maintenance schedule and introduces a potential point of contamination in clean environments. A key advantage of the diaphragm-style coupling is that it is maintenance-free. Its flexing motion does not involve any sliding or rubbing between Coupling Components, eliminating the need for lubrication entirely. This results in cleaner, more reliable long-term operation with lower lifecycle costs. In terms of Torque Transmission, both are capable, but the diaphragm type provides smoother, more constant velocity transmission, as it avoids the minute backlash and clearance inherent in gear teeth meshing.

Advanced Design Features and Key Coupling Applications

The evolution of coupling technology has led to significant design improvements, such as the innovative Tapered Sleeve Diaphragm Coupling. This advanced design incorporates a tapered sleeve mechanism that allows for remarkably quick and easy installation and removal, drastically reducing machinery downtime during maintenance or component swaps. This feature is invaluable in fast-paced industries where efficiency is paramount. The inherent precision and fatigue resistance of this design make it ideal for a wide range of demanding Coupling Applications. In aerospace, it ensures reliability in critical systems. In high-performance automotive and heavy machinery industries, its ability to provide smooth, quiet operation while handling immense torque and compensating for misalignment is indispensable. The torsionally rigid structure guarantees that power is conveyed effectively without compromising system performance or integrity, making it a superior choice for today's advanced mechanical systems.