What is a Diaphragm Coupling?

A Diaphragm Coupling is a sophisticated type of Mechanical Coupling that uses a flexible, disc-shaped membrane, or diaphragm, to connect two shafts. Its primary purpose is to facilitate smooth Torque Transmission from a driving shaft to a driven shaft while accommodating angular, axial, and parallel misalignments. Unlike other couplings that might use elastomers or gears, this design relies on the flexing of its thin metal diaphragms. This all-metal construction means it requires no lubrication, making it a clean and maintenance-free option for a wide range of machinery.

Exploring the Diaphragm Coupling Design and Components

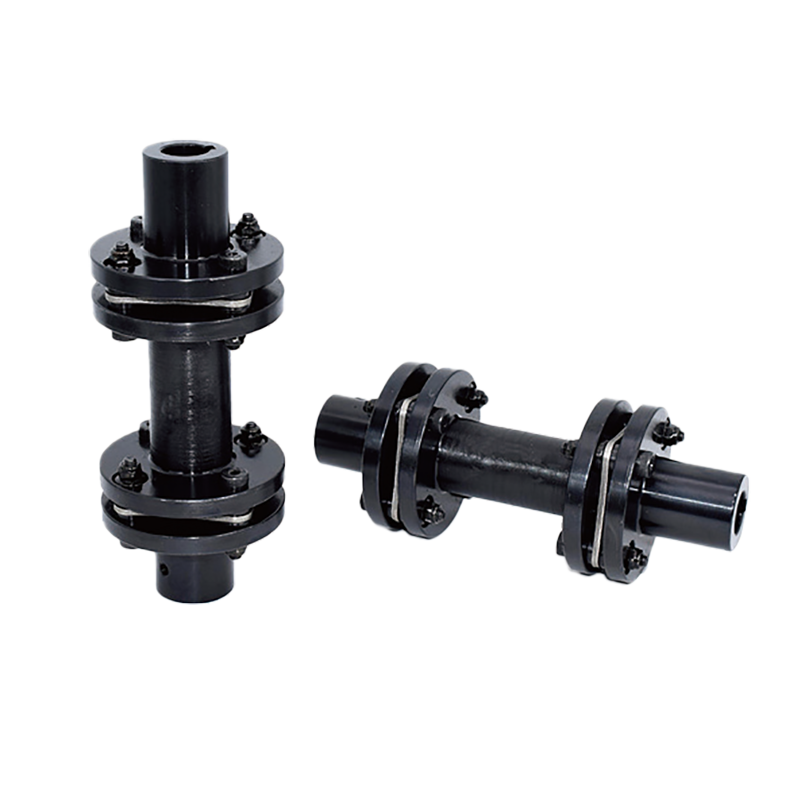

The genius of the Diaphragm Coupling Design lies in its simplicity and robustness. The core Coupling Components typically include two hubs, which mount onto the shafts, and one or more flexible diaphragm packs bolted between them. High-performance models, like the Tapered Sleeve Diaphragm Coupling, often feature advanced elements such as dual diaphragm layers for superior torsional flexibility and misalignment compensation. A unique design element like a tapered sleeve mechanism greatly simplifies installation and ensures a secure, concentric fit, significantly reducing maintenance downtime. This construction, crafted from high-quality steel, is built to be resilient and durable under immense operational stress.

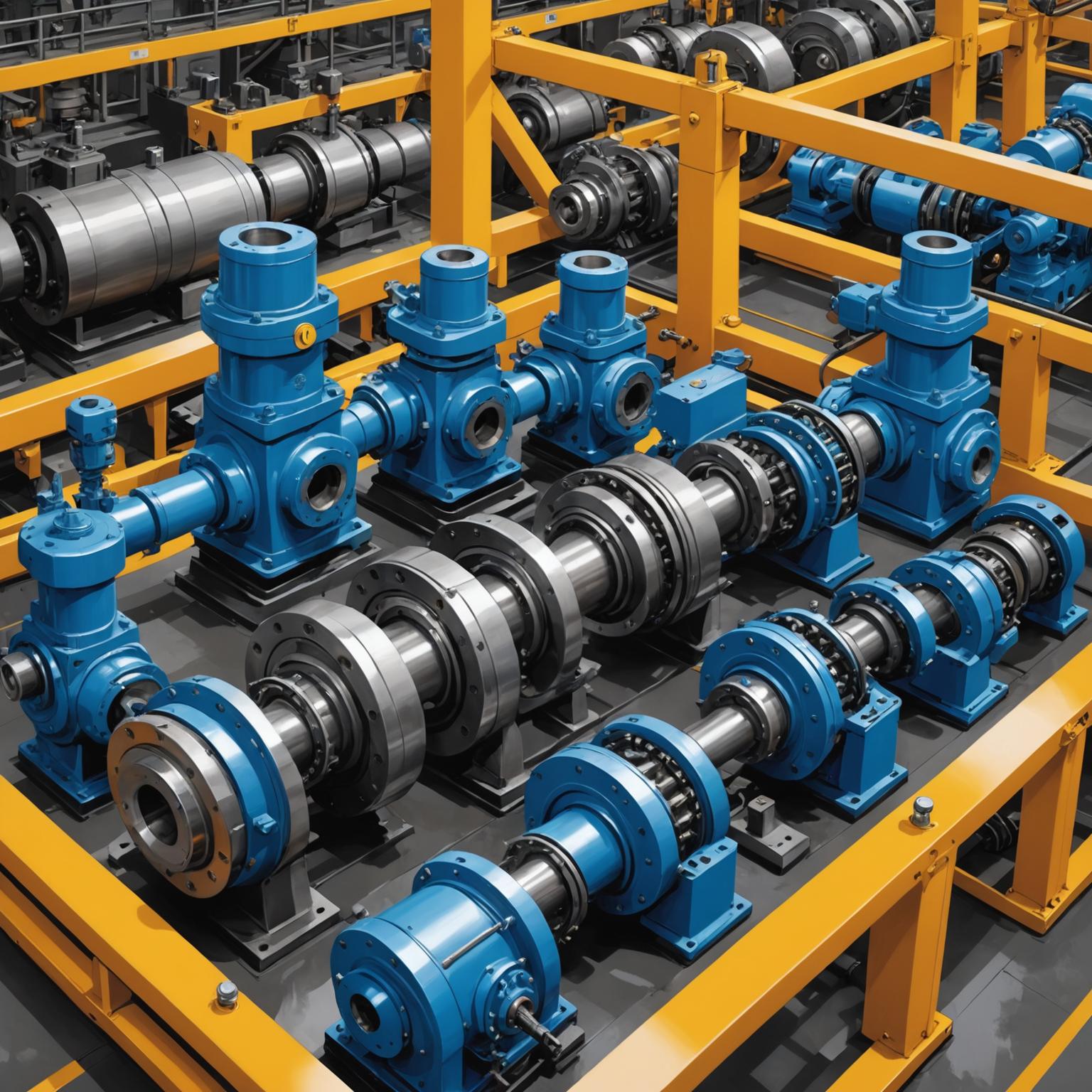

Where and Why to Use Diaphragm Couplings

The unique characteristics of these couplings make them ideal for a host of demanding Coupling Applications. They excel in high-speed and high-torque environments where precision is non-negotiable. You will commonly find them in gas turbines, compressors, industrial pumps, generators, and advanced manufacturing equipment. The key advantages are their high torsional stiffness, zero backlash, and ability to operate at high temperatures without degradation. Furthermore, their all-metal, corrosion-resistant build ensures they can perform reliably in harsh operating conditions, offering exceptional service life and quiet, smooth operation.

A Practical Guide to Selecting and Installing Your Coupling

Choosing the correct coupling is critical for system performance and longevity. When selecting a Diaphragm Coupling, you must consider factors such as the required torque capacity, maximum operational speed (RPM), shaft diameters, and the expected degree of misalignment. Always consult manufacturer specifications to ensure the chosen model meets your application's needs. During installation, even though these are Flexible Couplings designed to handle misalignment, achieving the best possible shaft alignment will drastically reduce stress on the components and extend the coupling’s life. Modern designs with features like tapered sleeves make the installation process much more straightforward, but verifying alignment remains a best practice for maximizing equipment performance and reliability.

Conclusion: The Modern Choice for Powertrain Connections

In summary, the Diaphragm Coupling represents a premier choice for modern industrial powertrains. It delivers exceptional performance by combining high-fidelity Torque Transmission with the ability to manage shaft misalignment effectively. Its maintenance-free design, durability, and suitability for high-performance applications make it a cost-effective and reliable component for any system where precision and uptime are paramount. By integrating an advanced coupling solution, you are not just connecting shafts; you are enhancing the endurance and efficiency of your entire operation.